You know that soldering is a useful skill to have. You also know that when you have sufficient knowledge about soldering, you can actually use it professionally or for your DIY projects.

You are fully aware that knowing the techniques to use a soldering iron is the first step you have to take in order to learn soldering properly. You are searching for a detailed guide that’ll give you clear instructions on how to use a soldering iron. If this is the case, then you can be sure that you’ve come to the right place.

In this post, we are going to dive deep into what does soldering actually mean, safety measures you need to take while using soldering iron, how to use a soldering iron and much more.

So without any further delay, let’s get started!

What does Soldering Actually Mean?

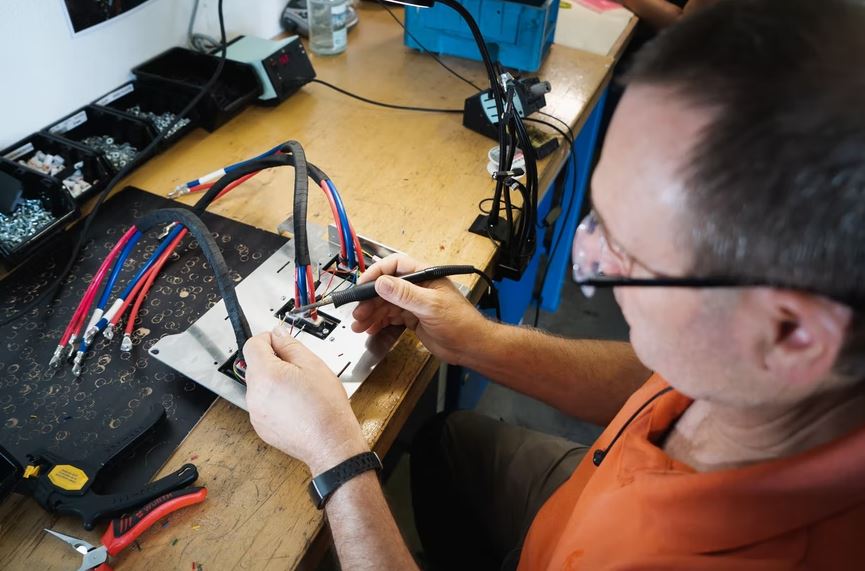

Soldering is a method that is used to join two different parts together. Soldering is generally used to join wires, cables and to repair steal-based equipments. The metal that is used to bond between the joints is called solder.

Solder is a metal alloy that is made of either tin or lead. It is melted with the help of a hot iron. The iron is heated over 600 degrees Fahrenheit and the tip of the iron is used to apply solder. Once it is applied, the surface is left to cool itself and that aids in creating a strong bond between 2 components.

Safety Mesures You must Take when Handling Soldering Iron

Before you learn to use a soldering iron, it is important that you have necessary knowledge on the safety mesures you need to take when using this equipment.

You may worry about damaging the equipment if you’ve never used a soldering iron before. But you might not know that a soldering iron poses serious dangers to yourself.

Kindly remember that a soldering iron is heated over 600 degrees Fahrenheit and that is seriously hot. And the solder is itself a molten metal.

So if you accidentally touch the iron or the solder that you apply falls into your eyes due to heavy breeze, the consequences are irreversible. So make sure to wear protective glasses for your eyes, wear tight-fit clothes, and avoid wearing loose clothes and wear protective hand gloves.

Also, remember that solder is made of lead and tin. So whenever you finish handling it, make sure to wash your hands thoroughly.

Kindly ensure that you are soldering in a well ventilated area. This is particularly important because the fumes from the rosin and the solder can be detrimental to your lung health when inhaled directly. Take necessary precautions before you start to use a soldering iron.

Steps You Need to Take in Order to Clean and tin the Tip of the Soldering Iron

It is crucial that the tip of your soldering iron must be free from previously applied solder to conduct heat properly. When the iron is exposed to air, it actually oxidizes and insulates against heat. A soldering iron must conduct heat properly so that you’ll be able to apply solder effectively and efficiently.

A dirty tip means that you have to hold the iron for a longer period of time so that the solder gets applied strongly. But there is also a possibility that the equipment can be damaged due to excess heat exposure.

In order to remove the old solder from the tip of your soldering iron, keep a wet sponge nearby. Once you heat the iron fully, scrape it softly against the sponge to remove old solder. After you complete the process, your soldering iron’s tip should be nice and shiny or pretty close to it.

The next step is to tin the tip. This’ll eventually protect the tip and let it conduct heat significantly better. On the fully heated iron, carefully apply fresh solder with you wearing the protective gloves for your hands. After that, coat the tip of the iron.

If you do this process correctly, the tip will still be shiny. As soon as you tin the tip, start soldering components and creating joints. After making few joints, clean and re-tin. Repeat this process until you put away the soldering iron into the storage.

It’ll definitely increase the lifespan of your equipment and a good soldering iron must last for a long time.

How to Use a Soldering Iron?

Here’s a step by step instructions on how to use a soldering iron.

- The first step is to hold the soldering iron in one hand and a long piece of solder in another hand. Make sure that you hold the iron in your dominant hand.

- When you solder 2 components together, first touch the iron in the area where both join.

- Keep the iron there for a second and then, gently slide the solder into the tip of the iron. Apply the solder evenly to the joint.

- Depending on the amount of solder you need for an even joint, keep the iron there on the joint itself.

- The total amount of solder required for a particular joint comes down to the equipment you are repairing and the components you have to join. So read the instructions provided on the solder package to determine the end result.

- Next, pull away the solder and keep holding the iron for some time. This helps the already applied solder to melt, pool and form a strong joint.

- After a second, remove the iron from the joint.

- The solder application process will be over within 5 to 10 seconds.

- Leave the solder applied on the joints untouched. It cools pretty quickly but if you move the equipment or you blow on the joint, it deteriorates. What it means is that the joint won’t be stronger.

- The perfect soldering should look like the solder is applied even and uniform, must present a flat picture and it must form a strong joint.

Conclusion

We hope that our detailed guide on how to use a soldering iron would have provided you a clear overview. As we’ve mentioned earlier, soldering is a good skill to have. But thoroughly understand about using a soldering iron before you start soldering.

There is a serious danger involved with this equipment, so take all the necessary safety measurements before you use it.

Want to include your thoughts about this guide? Share them away in the comments section below!

FAQs about Soldering Iron

What are the Metals Used in Soldering?

In the initial days, the major material used in soldering is lead. And overtime, lead-based solders are replaced by lead-free solders and they include materials like antimony, bismuth, brass, copper, indium, tin and silver.

Which Flux is the Right One to be used for Soldering Purposes?

The flux helps clean the metal from impurities such as dirt, oil and unnecessary oxidation. So the rosin flux is the ideal one to be used for soldering purposes.